Initial Service Line Inventory due on October 16, 2024

What is the inventory?

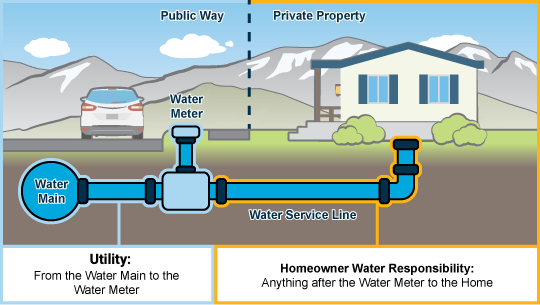

The lead service line inventory is something that all Community and Non-Transient Non-Community Systems have to complete by Oct. 16 2024. Every service line in your system, both the utility side and the customer side, needs to be identified within four categories: lead, non-lead, galvanized requiring replacement (GRR), or unknown. You are not expected to find out every single line when you submit your initial inventory in October. However, finding out as much as you can now is in your best interest.

WATCH: July 2024 Lead service line inventory webinar recording

How to complete the inventory

We do not expect all water systems to follow this method. If you would like to complete your inventory with a different method, you may submit your method proposal for DDW review and approval.

Before you start:

1

Determine if your water system is a Community or Non-Transient Non-Community (NTNC) System (Transient Non-Community systems do not need to comply with this requirement).

2

Then decide if your water system wants to participate in either funding program provided by the state. See Funding Options on the main page.

3

Download the inventory template and follow along to complete your inventory.

Step-by-step overview

Perform a records review (customer side and utility side)

Complete the Minimum Service Line Material Verification (MSLMV) process to determine which service lines need field verification

Step 2.1 : Identify all known service lines

A system may avoid the Initial Predictive Modeling Process if all potable water service lines within the system meet the strict definition of “known.” Go to Step 5 if all your service lines are defined as “known.”

Step 2.2 & 2.3 : Identify all the service lines that need physical verification

Step 2.4 : Conduct verification using an approved method

Step 2.5 : Record the results of the verification

Assess the reliability of the records

Classify material type of remaining unknown service lines

- No GRR or Lead found in records review or MSLMV Process

- GRR or Lead found in records review or MSLMV process

Step 5

Assess the reliability of the records

Submit either a completed non-lead form or initial lead inventory template.

Step 6

Update the inventory template annually by October 16 of each year if inventory has unknowns, GRRs, or lead, and submit online

Detailed steps

Full guidance document

For even more details than what are listed here, reference the Lead Service Line Inventory Guidance

Step 1 – Organize and review existing records

Review the these sources of information to identify service line materials for the initial Service Line Inventory:

- All construction and plumbing codes, permits, existing records, or other documentation which indicate the service line materials used to connect structures to the distribution system.

- All system records, including distribution system maps and drawings (e.g., as-builts), historical records on each service line (e.g., tap cards, permits), building construction dates, operation and maintenance records, meter installation records, historical capital improvement or master plans, and standard operating procedures.

- All inspections and records of the distribution system that indicate the material of all service lines on both utility side and customer side

- Lead and copper sample site plans.

- Any resource, information, or identification method provided or required by the Division of Drinking Water to assess service line materials.

- Other sources of information not listed, if approved by the Division of Drinking Water.

Consult the EPA’s Guidance for Developing and Maintaining a Service Line Inventory for a comprehensive overview of the records that are required to be reviewed.

Additionally, we may accept firsthand observations from long time staff members, plumbers, operators, contractors etc. as evidence. We will be accepting firsthand observation through certification only for the identification of the service line material for the utility side in the initial inventory. To use firsthand observation for the customer side, you must receive approval from the Division of Drinking Water. Customer-side classifications based on firsthand observation will likely require additional verification. A ‘Service Line Material Certification’ must be submitted for firsthand observation to us with the initial service line inventory.

See the Service Line Material Certification form.

Line categorization

Each service line, or portion of the service line where ownership is split, must be categorized as one of the following:

- Lead: A portion of pipe that is made of lead, which connects the water main to the building inlet. A lead service line may be owned by the water system, owned by the property owner, or both.

- Galvanized requiring replacement (GRR): A service line that was, or is currently, downstream of a lead service line or service line of unknown material. See how to determine below if a galvanized service line is GRR if the water system does not have records.

- Non-lead: Where the service line is determined through an evidence-based record, method, or technique not to be lead or galvanized requiring replacement.

- Lead-status unknown: Where the service line material is not known to be lead, galvanized requiring replacement, or non-lead, such as where there is no documented evidence supporting material classification.

Determining galvanized requiring replacement lines if records are not available

Your system may not have records that indicate whether or not galvanized service lines have ever been downstream of lead. If this arises, your system may determine that a galvanized service line does not require replacement (i.e., can be classified as non-lead) only if:

- No lead service lines are found within the water system service area during the course of records review;

- There are no known records or knowledge of previous lead service line replacement programs; and

- No lead service lines have been found during field investigations.

If your system has classified galvanized lines as not requiring replacement based on this criteria and discovers lead service lines or lead upstream of a galvanized line at any point in the future, you must inform us within 30 days. We will work with your system regarding further investigations or may classify similar galvanized lines as galvanized requiring replacement.

Note: If your system is unable to demonstrate that all the above criteria have been met or cannot demonstrate through other methods detailed in the Detailed Inventory Guideline document for identification i.e. inspections, modeling, sampling, or firsthand observation, presume there was an upstream lead service liens and the galvanized line must be classified as “galvanized requiring replacement” per the LCRR.

Step 2 & 2.1 – Minimum service line material verification process

The Minimum Service Line Material Verification process allows water systems to avoid physically checking all unknown service lines. Instead, they can randomly select and verify a portion of these lines. This process will help figure out how common different types of pipes are in the water system. Also, if you find pipes made of lead or galvanized steel that need to be replaced, this process will give you a starting point for checking what the pipes are made of and planning how to replace them.

Minimum Service Line Material Verification

(MSLMV)

- Create a tool for tracking records and materials during verifications

- Identify all unknown service lines

- Determine how many services lines must be serviced

- Randomly select service lines for verification

- Conduct verifications using approved methods

- Retain identification records

- Record the results of the verifications in the form created in MSLMV

The Minimum Service Line Material Verification process serves two key purposes:

- Establishes the reliability and completeness of service line records. Record reliability can vary widely, and it is important that systems take steps to verify both service line materials and records.

- Develop a statistical understanding of the materials in the distribution system to direct any further service line verification or replacement efforts.

The Minimum Service Line Material Verification process does NOT provide:

- The service line material of every building served; or

- The extent to which some parts of the distribution system have different rates of certain materials in the service lines compared to the average rate for the whole system.

2.1. Identify all known service lines

For the purpose of the Minimum Service Line Verification process, use a conservative approach to determine when a service line’s material can be characterized as “known” based on records or physical verification and can be excluded from the verification process.

Any service line that does not meet one of the criteria below is considered “unknown” for the Minimum Service Line Material Verification process. The “unknowns” should be included in the list of locations from which a set of sites will be randomly selected for verification.

A system may avoid the Minimum Service Line Material Verification process if all potable water service lines within the system meet the definition of “known” described below.

- The service line was recently physically verified and all the following apply:

- The location where the service line was inspected complies with the approved field verification locations identified in this guidance

- The physically verified material was well documented at each verification point; AND

- The water system has not observed deviations from these records during operations and maintenance; OR

- Regulations were in place at the time the service line was installed specifying materials used in service line construction; AND the system has not observed deviations from these regulation(s) during operations and maintenance; OR

- The water system has records that provide the material type of service lines on the utility side that have been deemed to be reliable. This includes firsthand observations from long time staff members, plumbers, operators, contractors, etc. The ‘Service Line Material Certification’ must be submitted for anecdotal reports to us.

Find the Service Line Material Certification form online.

Additionally, if a site meets any of the following criteria, the service line can be categorized as “non-lead” and excluded from the verification process:

- Service lines four inches in diameter or more.

- For service lines two inches in diameter or more but less than four inches in diameter and the system has reviewed available records and there is no evidence indicating the presence of lead service lines.

- Water systems without historical records must review maintenance and/or repair records and firsthand observations from staff or local plumbers (if available) to demonstrate that there is no evidence of lead service lines two inches or more in diameter.

- Any service line that is two inches or more in diameter is found to be lead, further field verification may be required for service lines of that size.

- Service lines installed after Utah’s state lead ban of April 1989, and no earlier local regulation specifying allowable materials or banning lead exists.

- Service lines installed between January 1, 1970 to April, 1989, and the water system has reviewed available records and there is no evidence indicating the presence of lead service lines and/or goosenecks installed after 1969.

- Systems without historical records must review maintenance and/or repair records and firsthand observations from staff or local plumbers (if available) to demonstrate that there is no evidence of lead service lines and/or goosenecks installed after 1969.

- Systems with confirmed lead service lines must carefully verify construction records to confirm that the service line doesn’t pre-date the current structure.

- If lead service lines are found connected to a building constructed after January 1, 1970, following the submittal of the initial inventory, further field verifications may be required for buildings constructed between January 1, 1970, to April, 1989.

Note: In the proposed EPA Lead and Copper Rule Improvements (LCRI), systems must validate the accuracy of a pool of service lines that were determined to be non-lead through any method other than record reviews and 2-point field verification (utility side and customer side) no later than ten years after the final LCRI is published. Service lines that were determined to be non-lead by using the 1970 cutoff date or by using firsthand observations may require future validation through this proposed requirement.

Step 2.2 & 2.3 – Identify all the service lines that need physical verification

2.2 Identify all the service lines that need physical verification

- Public water systems with fewer than 1,500 unknown service lines: Must physically verify according to the requirements in Step 2.3, at least 20 percent of the total number of unknown service lines.

- Public water systems with more than 1,500 unknown service lines: Must physically verify according to the requirements in Step 2.3 enough lines to reach a minimum 95 percent confidence level. See Appendix A to determine the number of service lines requiring verification.

2.3 Randomly select service lines for physical inspection

- From the list of unknown service lines identified in Step 2.1 and the number from Step 2.2, randomly select service lines to be physically inspected as determined in Step 2.2. Selection must be uniformly random and not selected based on any specific criteria which can introduce bias. In other words, each unknown service line must have an equal chance of being chosen for verification. See Appendix B for an easy way to generate a uniformly random set of service lines for inspection.

- There may be some concern that using random selection will not provide adequate representation of buildings in the age range where lead is most likely to be found. It is important to note that the intent of the Minimum Service Line Material Verification Process is to gather information that is not biased. It may be tempting to introduce “logic” to the site selection process, such as selecting within certain periods of construction or targeting portions of the distribution system. However, doing so can unintentionally bias the data set. Systems must use a truly random selection method equivalent to the method described in Appendix B.

Note: As it may not be possible to gain access to private property at all the randomly selected sites, the water system may want to create a list of randomly selected service lines that exceeds the number of lines needed for verification to enable alternate locations that can be used if access is denied by a property owner (e.g., 10% more than the minimum sample size).

Step 2.4 – Conduct verification using an approved method

Every part of the unknown service lines, whether owned by the system or the customer, needs to be checked using approved verification methods by the Division of Drinking Water. These methods can be customer surveys, tests on materials, inspecting meter pits when appropriate, and excavation.

The system has to keep records about identifying these service lines. It’s suggested to take photos of the lines to visually confirm them. Water systems should have clear standard operating procedures for how they check these lines and share them if asked by the Division of Drinking Water.

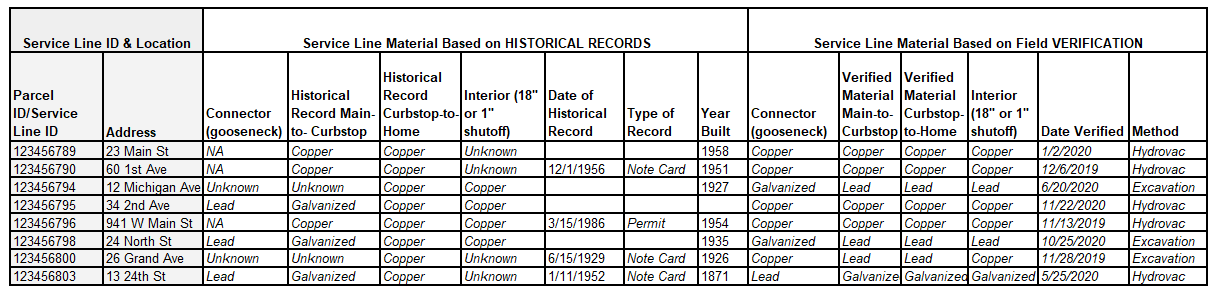

Step 2.5 – Record the results of verification

In a spreadsheet or tracking tool, enter the service line material observed at each point of the service line during the physical verification conducted in Step 2.4. Always record the actual material observed, such as lead, copper, plastic, galvanized steel, or other. Avoid using “non-lead.”

Note: This is only meant to serve as an example. Water systems should add additional columns as needed to capture information useful to the verification process and completion of the Inventory Template.

Step 3 – Assess the reliability of the records

- The findings from the physical verification process can be used to assess the reliability of historical records that were previously determined to be unreliable (ie. firsthand observations for the customer side).

- Existing records can include all relevant information related to the service line material (tap cards, as-builts, permits, institutional knowledge, etc.).

- Additional information that may be useful for comparison may include service line age, water main age, building age, timeline of projects, contracted work agreements, data collected during water meter replacements, and various controls or regulations.

- Relevant information/records may vary from system to system. It is important to identify all useful information and conduct comparisons in a logical/methodical manner. Once water systems have compiled all relevant information, they must compare the findings to the data gathered during the Minimum Service Line Material Verification in Step 2.

- Ask questions such as:

- Did the physical verification confirm existing records were accurate?

- Is institutional knowledge reliable?

- Were there errors in the data?

- Are there patterns in reliable versus unreliable data, etc.?

- By comparing the records in different ways, systems can become more sure about what they can and can’t use from each record.

Step 4 – Classify material type of remaining unknown service lines

Step 4.1: No lead service line or galvanized requiring replacement found in records and/or during Minimum Service Line Material Verification process

4.1.1 Minimum Service Line Material Verification process confirms records are reliable and has records for all service lines

If a system has historical records documenting the materials of all service lines in the distribution system (both public and private property), they can have high confidence that existing records are reliable and can be used to complete the Non-Lead Form.

4.1.2 Minimum Service Line Material Verification process confirms records are reliable and water system has records for some service lines

If a system has historical records documenting the materials of some of the service lines in the distribution system (both public and private property), they can classify the service line materials of the service lines for which they have records. Based on the information obtained from both the Minimum Service Line Material Verification process and available historical records, the water system can, with a 95% confidence, classify remaining service lines as non-lead and complete the Non-Lead Form.

4.1.3 Records are deemed unreliable based on Minimum Service Line Material Verification process or no records exist

As long as no lead service lines were found during the Minimum Service Line Material Verification process, and there is no record or knowledge of lead service lines or lead service line replacements, water system may classify all unknowns as non-lead based on the information obtained from the Minimum Service Line Material Verification process and complete the Non-Lead Form.

Step 4.2: Lead or galvanized requiring replacement found in records and/or during Minimum Service Line Material Verification process

After reviewing the accuracy of records, water systems must determine which records are reliable for classifying unknown service lines as known materials. Systems that found lead service lines or galvanized requiring replacement during the record review or verification process may find themselves in one of the following categories:

4.2.1: Minimum Service Line Material Verification process confirms records are reliable and has records for all service lines

If a water system has historical records documenting the materials of all service lines in the distribution system (both public and private property) the system can have high confidence that existing records are reliable and can be used to complete their Service Line Inventory, making sure to categorize each service line with the appropriate material type based on the records.

4.2.2: Records are deemed unreliable or no records exist

If records did not match the materials found during the minimum service line material verification process, or the water system has no records, the water system must use the data collected during the minimum service line material verification process to determine the attributes associated with different material types identified, and proceed as follows:

- Based on the information obtained from both the minimum service line material verification process and available historical records, the water system may be able to identify attributes (age of construction, neighborhood, service area, etc.) among service lines of non-lead material type to predict unknown service lines with the same attributes. Water systems may submit a prediction proposal for Division of Drinking water review and approval.

If lead or galvanized requiring replacements service lines are found in records or through the minimum service line material verification process, the water system must take the following steps:

The water system should determine similar attributes among those sites that were found to have lead or galvanized requiring replacement service lines (e.g., build date, neighborhood etc.).

The water system must then identify additional sites within its service area with unknown service line material and having similar attributes to those identified in Step 1.

Randomly select enough sites within the service area with those attributes to meet the minimum number requiring verification (Appendix A).

The water system must begin physical verification of these sites.

No lead or galvanized requiring replacement service lines found:

If no lead or galvanized requiring replacement service lines are found through this process, then the attributes identified may not be correct. The systems should conduct an additional investigation to determine other attributes. After identifying other attributes, the water system should repeat the steps outlined above. If no additional attributes can be identified, the lead or galvanized requiring replacement service lines identified in the minimum service line material verification process may be anomalies and the sites with these attributes may be able to be categorized as non-lead.

Lead or galvanized requiring replacement service lines found:

If the water system finds lead or galvanized requiring replacement service lines, then all sites within the service area with similar attributes should be categorized as unknown until they can be physically verified.

4.2.3: Minimum Service Line Material Verification process confirms records are reliable, has records for some service lines

If a water system has historical records documenting the materials of some of the service lines in the distribution system (both public and private property), they can classify the service line materials of the service lines for which they have records. For the remaining unknown service lines water systems may follow the process outlined in 4.2.2.